The strategic position of lepidolite for lithium extraction has been improved

Extraction of lithium from mica: technological breakthrough, becoming an important part of lithium resource supply

With the breakthrough of lithium mica extraction technology and the progress of technology, lithium mica extraction of lithium has achieved large-scale production, the production cost has reached the average cost of lithium industry, and the product is relatively stable, which has been recognized by downstream cathode material manufacturers. Lepidolite has gradually become an important part of lithium resource supply.

The development of lithium mica has become a strategic need

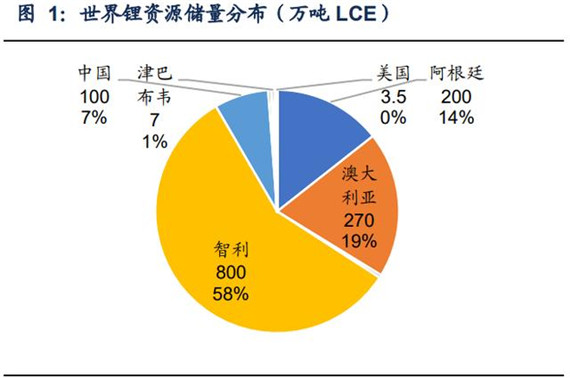

China's dependence on lithium resources is as high as 70%. The world's lithium resources are mainly distributed in Chile, Australia and Argentina, and China's lithium resource reserves account for only 7%. At the same time, China has a large capacity of lithium salt. By 2020, the capacity of lithium carbonate and lithium hydroxide is about 506900 tons of LCE, and the global capacity of lithium salt is about 785700 tons of LCE, accounting for about 65% of the world. Therefore, China's lithium resources are highly dependent on foreign countries. About 70% of lithium mines depend on overseas imports, of which Australia's import proportion reaches 60%.

Since 2018, China Australia relations have gradually deteriorated. In May 2021, the national development and Reform Commission issued a statement announcing the suspension of the activities under the telephone system of China Australia strategic economy jointly led by relevant departments of the Australian federal government, and China Australia relations entered a state of tension.

As the core material of lithium new energy, lithium resources, known as "white oil", has risen to China's national strategic reserve resources since 2016, and the exploitation of resources is protected by the state. In order to deal with the problem of lithium resource supply security caused by the deterioration of China Australia relations, the intensity and speed of domestic lithium resource development may be strengthened.

China's lithium resources are mainly salt lakes, spodumene and lepidolite. Salt lake lithium accounts for 83%, mainly distributed in Qinghai and Tibet; Spodumene accounts for 15%, mainly distributed in Sichuan; Lepidolite accounts for 2%, mainly distributed in Jiangxi.

The lithium extraction process of lithium mica has been continuously optimized and upgraded

The methods of extracting lithium from lepidolite mainly include lime roasting, sulfuric acid roasting, sulfate roasting, chlorination roasting and pressure boiling.

Compared with spodumene, lepidolite mainly faces more impurities in the extraction process, especially fluorine-containing elements. Mica exists in the form of silicate and has a relatively tight structure. In the early stage, it needs high-temperature roasting and defluorination treatment to loosen the raw ore structure, and then carry out the next grinding. In addition, in the later stage, fluorine element is easy to produce hydrofluoric acid in the reaction process, which corrodes the equipment, resulting in continuous production.

Limestone roasting method is mainly used in the initial stage of lithium extraction from lepidolite. Due to the complex impurity removal process and large amount of waste residue, it has been gradually eliminated. There are many corrosion resistance requirements for sulfuric acid production equipment after sulfuric acid method is adopted, but the corrosion resistance of sulfuric acid production equipment is high. At present, most enterprises in Yichun Area Use sulfate roasting method for production. In the initial stage, potassium sulfate is mainly used. Now, sodium sulfate and sodium potassium sulfate are used as substitutes to further reduce the production cost.

Post time: Apr-19-2022