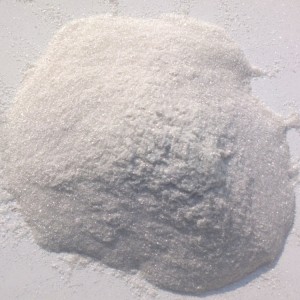

Wet mica powder

Product description

In terms of insulating materials

Many foreign manufacturers have long used wet mica in the manufacture of rubber tires. From the surface to prevent the adhesion of inner and outer tires, it is also used as the release agent of rubber products, in addition, it is used to manufacture cables, which not only improves the insulation, but also prevents the sheath from hardening and the adhesion of cable cores.

In terms of Plastics

(1) The unique flake structure of mica makes it a typical reinforcement filler. The wet mica powder is mainly used to improve the toughness, heat resistance and dimensional stability of plastic products. Its contribution in this respect is better than any other inorganic filler. For example, polypropylene is used to make auto parts, such as hot valve shell, instrument panel, door panel, etc.

(2) manufacture auto parts with polyterephthalic acid and butanediol grease, including external decorations, components in the cab, etc.

(3) It is used in the manufacture of spray bathrooms, bath sanitary units, tank liners, etc.

(4) Use phenolic, epoxy, silicone and other aspects to manufacture electronic and electrical industrial components.

In fine chemicals and cosmetics

Due to the advantages of non-toxic and harmless wet mica powder, no peculiar smell, bright lubrication, no precipitation and easy dispersion, many manufacturers at home and abroad have widely used wet mica in fine chemicals, and now mica is also used in many cosmetics, adding brilliant colors to the products.

High grade paint

Wet mica powder can replace zinc powder, aluminum powder, magnesium powder and titanium powder in high-grade paint. Wet mica powder and sericite powder have been widely used in paint industry in domestic and foreign paint factories.

In the manufacture of pearlescent pigments

Wet mica powder is the main raw material of mica pearlescent pigment.

Common specifications: 100 mesh, 200 mesh, 325 mesh, 400 mesh, 600 mesh, 800 mesh, 1250 mesh, etc.